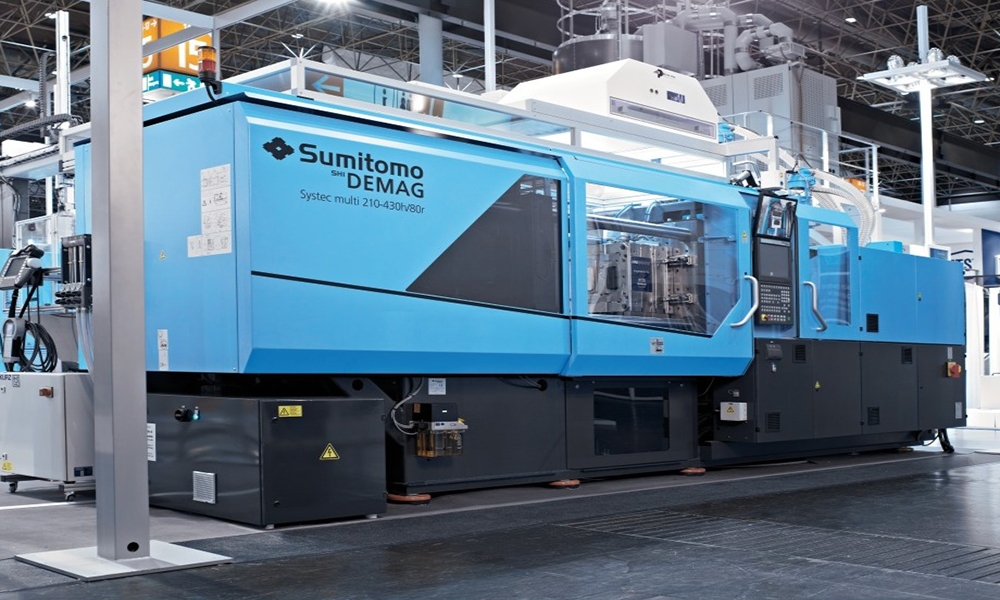

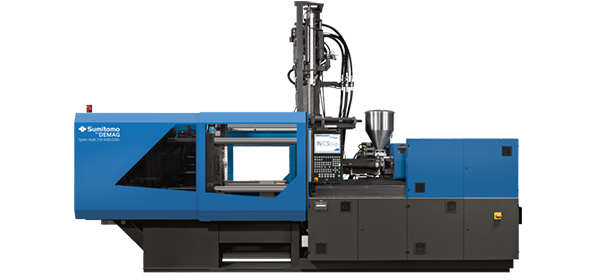

Multi

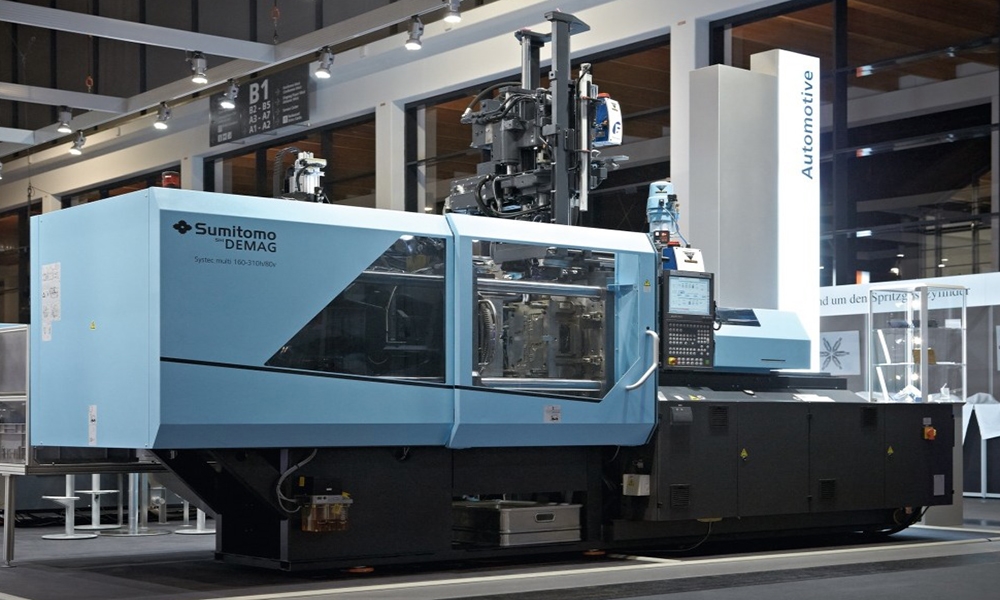

Systec multi – the technology for a wide range of materials

The growing variety of possible material combinations in forwardlooking sectors of industry demands high-performance and flexible multi-component technologies. The Systec multi is ready today to face the challenges of tomorrow.

Flexible and versatile

Suitable for all common multi-component injection-moulding processes: bi-injection, composite injection-moulding and sandwich technology, positioning and turning of shaped components

Combination of a wide range of plastics, metals and semi-finished products into homogenous and heterogeneous compounds

Direct connection of adhesion-compatible materials and mechanical combination of adhesion-incompatible materials

Production of mobile, non-connective components with adhesioncompatible materials

Individual extension capability

Modular design for individual machine configuration

Optionally two to four injection units in the closing force range of 1,200 - 10,000 kN

Wide range of additional packages for multi-colour and multicomponent injection-moulding

For more information: http://www.sumitomo-shi-demag.eu/products/systec-multi-multi-component-injection-moulding-machines.html