Compression

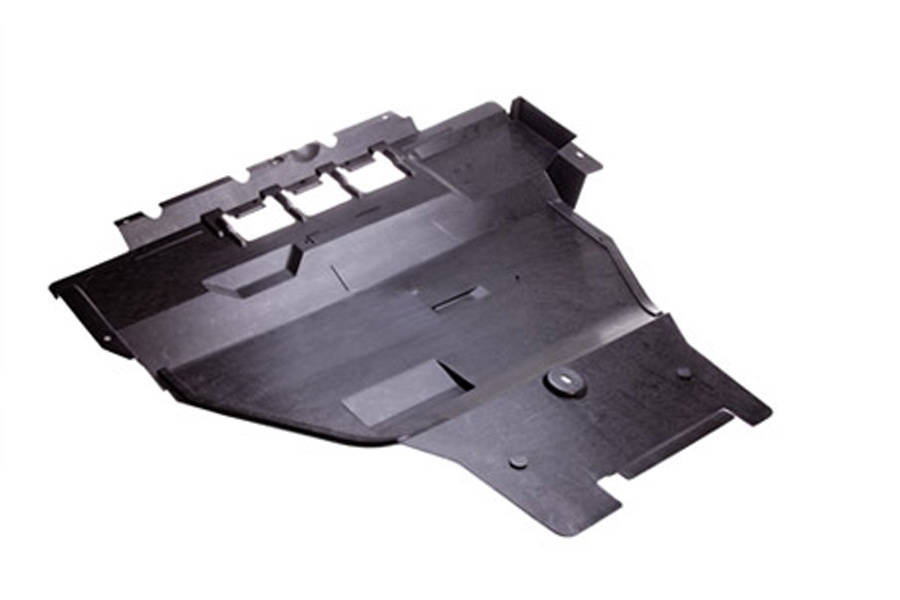

The term “injection-compression moulding“ means the introduction of thermoplastic polymer melt into a slightly opened mould with simultaneous or subsequent compressing by an additional clamping stroke. This additional clamping stroke can be accomplished via the machine or via a compression punch in the mould. The cavity pressure building up in the mould is distributed in two dimensions more uniformly over the projected component surface, usually with the aim of improving the accurate reproduction of surface detail and the dimensional stabil- ity of the components. Injection-compression moulding processes are low-pressure processes, so as to not damage inserts such as decorative film or metal inserts. Injection-compression moulding processes are low-pressure processes so that, for instance, decorative trim or metal inserts are protected. It is precisely in the case of light engineering applications that low injection and follow-up pressures minimize internal stresses and, thus, have a strong influence on the optical properties. A suitable injection moulding machine must therefore feature not only a high degree of flexibility, but rather also very precise and reproducible movements.